CONFERENCES/PUBLICATIONS IN PEER-REVIEWED JOURNALS

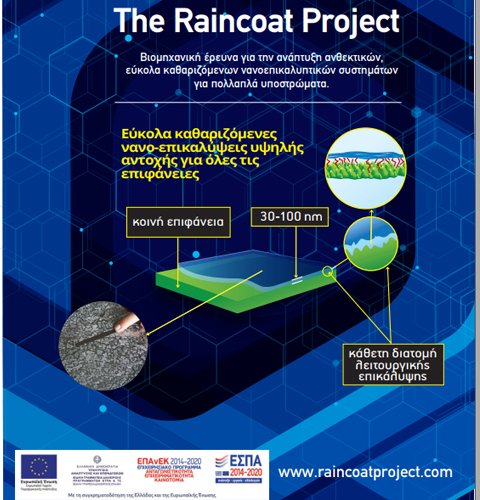

1. Durable Self-Cleaning Coatings for Hard Surfaces, Dr. N.D. Papadopoulos, Dr. P. Vourna and S. Xafakis, Open Access Journal of Biomedical science, 2022, 4(6), 2209.

2.Dr. K. Giannakopoulos, Dr. N.D. Papadopoulos, P. Koutsaftiki, S. Xafakis, Designing a facile preparation mode for the development of transparent and durable anti-soiling coatings with enhanced anti-static properties, EUROMAT 2021: European Congress on Advanced Materials and Processes, Oral Presentation (Dr. K. Giannakopoulos).

3. P. Koutsaftiki, Dr. P. Vourna, S. Xafakis and Dr. N.D. Papadopoulos, Proposing a sustainable methodology for the development of a robust, anti-soiling transparent coating with enhanced antimicrobial properties for smooth, non-absorbent surfaces, Coatings Science International Conference, 2021, Poster presented by P. Koutsaftiki.

4. Dr. N.D Papadopoulos and Dr. P. Vourna, Proposing a sustainable strategy for the fabrication of robust anti-soiling coatings with enhanced antibacterial attributes for non-absorbent substrates, International journal of nanomaterials, nanotechnology and nanomedicine, 2022, 8 (1), pp. 1-4.

5. Dr. N.D. Papadopoulos, S. Xafakis, P.P. Falara and Dr. P. Vourna, A versatile approach towards development of robust transparent antisoiling coatings with antimicrobial activity for various substrates. Athens Conference on Advances in Chemistry, 2022, Presented by Dr. N.D. Papadopoulos.

6. Dr. N.D. Papadopoulos, P.P. Falara and Dr. P. Vourna, A versatile approach towards development of easy-to-clean transparent nanocoating systems with pronounced anti-static properties for various substrates, AIMS Materials Science, 2023, 10 (1), pp. 139-163.